Refraline’s specialisms lie in the installation, repair and maintenance of refractory and corrosion solutions for a wide range of industries, among them iron and steel, chemical and petrochemical, and power generation. Managing Director Manfred Rosch talks us through the company’s operations, and its plans to extend its footprint throughout Africa and beyond.

“At Refraline, we are a refractory engineering company,”summates Manfred Rosch, of the company with over 30 years of operational experience behind it. “We are installers, manufacturers and suppliers of refractory and corrosion materials and linings, based in Germiston, Johannesburg. We operate everywhere in South Africa, as well as in our neighbouring sub-Saharan countries like Namibia, Zimbabwe, Zambia and Botswana, alongside projects out in the Democratic Republic of Congo. We also do business in the Middle East, and in Madagascar, and we sometimes even work as far afield as in Asia and Australia, although these are not our regular territories.”

From its head office in Meadowdale, Germiston, Refraline’s reputation has been founded on the reliability, flexibility and fast response times with which it completes its work, seeing it undertake numerous high-value contracts throughout sub-Saharan Africa. “When I look back to when Refraline started in 1981,”continues Rosch, “since then we have grown to become a leading refractory engineering company in our market. It is a market which is not really growing which means we really have to fight, and must simply be better than our competitors. The fact that we have continued growing into a company which today has 300 million Rand turnover and more than 500 permanent employees is a real sign that our customers appreciate the service we offer to them.”

Manfred Rosch details how this confidence extends through the company’s dealings, with its reputation for peerless service bearing fruit in a scheme due to be completed this year, among its most notable successes of recent times. “Three years ago we started a buyback program to allow shares to be regained from the European entity Beroa, which by the end of the year will be complete. The result of this is that Refraline will be 100% South African owned. For us as management this was a vote of confidence, in the sense that our shareholders believed in investing back into their own company when the shares became available, and put up the money to purchase them.”

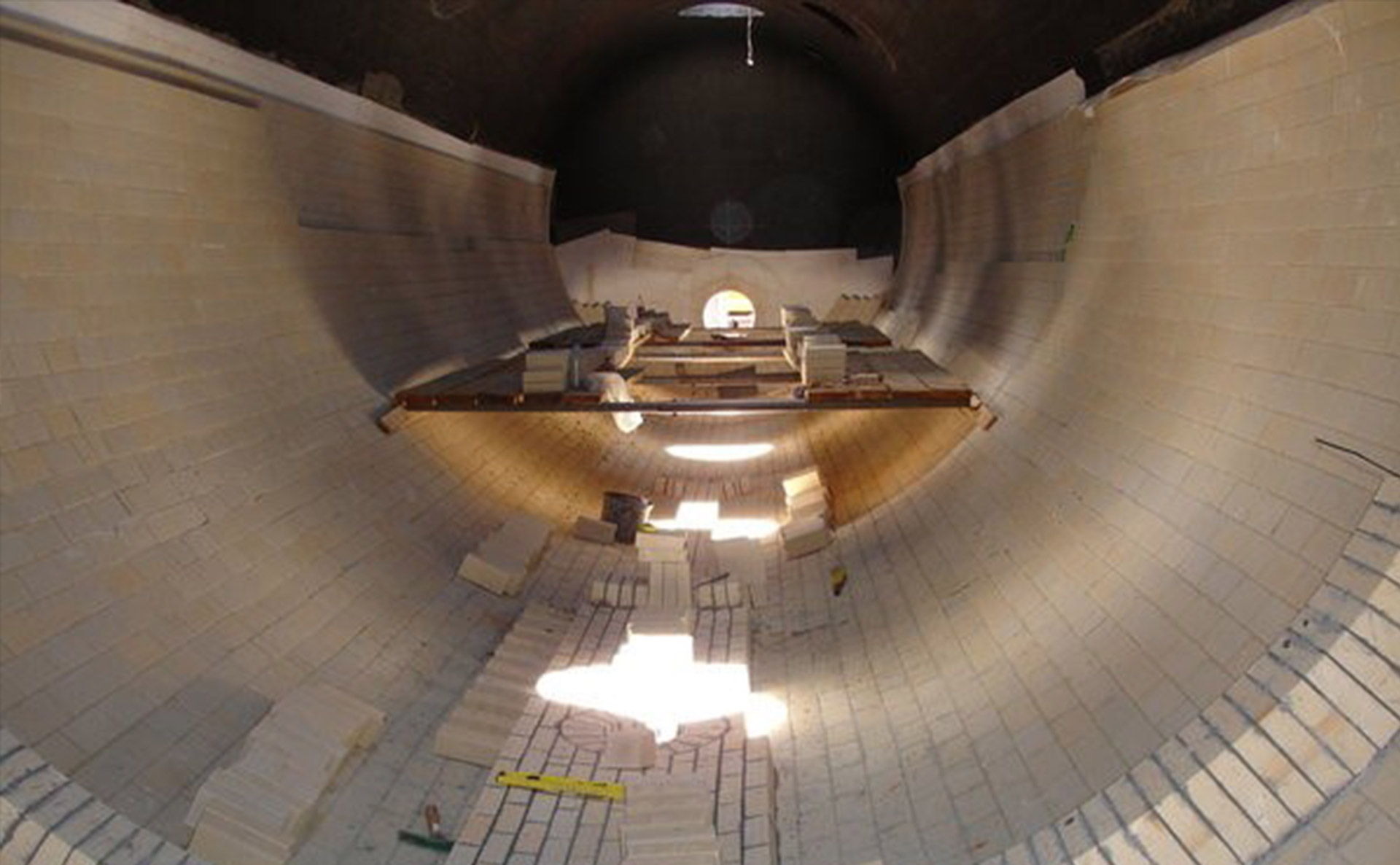

Refraline has developed high temperature materials to cover the full range of monolitics including Castables, Gunning, Ramming, Colloidal Silica Castables, Insulation Castables and Mortars. Our materials can be used up to 1800 deg C They are typically used in linings for furnaces, kilns and incinerators, while the corrosion scope of Refraline’s work comprises vessel such as acid towers and reactors, through to chimneys and corrosion resistant bricks and tiles for floors. “The key to our success,”explains Rosch, “is that we listen to our customers and develop products and installation techniques which will ultimately benefit them. We need to always challenge what we are doing and improve on what we did last time.”One example is the environmental friendly taphole clay that we have developed to improve the working conditions of our client’s workers who are using this product. Our clay does not contain any tar that burns of nasty volatiles which are causing a health risk.

The dual aspects of Refraline’s business affords a certain security, and allows the accrual of expertise in a variety of operations. “We have our two main fields of operation whereby refractories account for around 75% of our business, alongside the remaining 25% in corrosion linings. This split allows us to weather some storms, because in some years we have more success on the refractory side, while in other years the corrosion linings will perform better.”

“In this sense we have some diversification within our field, and our performance over the last couple of years has been highly pleasing.”This has not been easy to achieve, as Rosch details: “Even at the moment the commodities are in something of a ‘slow down’, with our customers really having to watch every cent that they spend, but as long as we can offer them the right product at the right price as well as solutions which end up bringing their overall plant cost down, they will continue to do business with us.”

Refraline is placed to handle several refractory contracts simultaneously, using its own sophisticated techniques and specialised construction equipment to fulfil all manner of jobs. For example, in removing the linings of kilns and ladles the company can boast remote-controlled Brokk MB 330 and MB 150 demolishing machines, which serve to significantly reduce downtime alongside increasing productivity and providing heightened safety. It has access to much other world-class equipment, such as the hydraulically operated, telescopic, rough terrain forklifts which deliver refractory materials to otherwise inaccessible locations, as well as special mixing and pneumatic conveying machinery and pneumatically operated bricking rigs.

In an industry as fast moving and ever-developing as this, Rosch explains that, “there are new technologies constantly appearing and we have to stay on top of new trends and materials. We evaluate them constantly to see if they would benefit our customers, and, if so, we will welcome them.”Refraline also clearly sees the importance of bringing its own products and ideas to the market, the impact of which on its business Rosch details. “We began manufacturing our own monolithic refractory material two years ago, and we’ve gained significantly more market share in this,”he states. “While the company is 30 years old we have only recently started manufacturing our own monolithics, so to gain such a market share in the field is very satisfying. We’ve developed a number of new products and challenged many practices, and as such we can offer better solutions to our customers which ultimately serve to improve the overall performance of their plant. That is our focus.”

This customer-centric approach is among the core facets of Refraline’s ethos, and has been responsible for a large art of its continued success since its inception. “We concentrate on our customer. People place a lot of confidence in us to fulfil their refractory services, and we have shown over the years that we can deliver good service at a competitive price. We always aim to look at the bigger picture in a client – it’s not always important how much someone pays for a refractory product, but how much that product can bring the plant availability up and the overall plant costs down.”

The weight of its collective experience has seen Refraline undertake jobs ever further afield, which becomes increasingly pertinent as Rosch lays out the current state of play within South Africa. “The industry at the moment is in something of a stagnant phase,”he admits. “There is no real growth coming through. In South Africa in particular we have our own challenges with some of our customers having to switch off capacity, as there is not enough electricity to power operations. These things then combine to have an impact on the overall growth of the industry.”

“There are always opportunities for us, but none of our competitors are sleeping,”he points out, “so we have to constantly reinvent ourselves and deliver quick service to make our customers happy with what we offer. We have many, many customers that have used us for ten, or even fifteen years, which indicates that we are already doing many things right within the field.”

The reputation it has earned and this tireless approach to expansion has already reaped significant rewards, as Rosch details just one aspect of Refraline’s global outlook. “We have secured a contract in Malaysia, a venture that we are taking on with a Malaysian refractory installation company. This will see us build two submerged arc furnaces for a South African vendor with whom we have already been working for over fifteen years, prompting them to give us their vote of confidence to build their furnaces in Malaysia. These are exciting projects for us where we can show our capabilities in other parts of the world.”

“We have to focus on finding growth for the company outside of the South African market,”says Rosch of the company’s plans going forward, “developing further into other African countries, and building further on the first installation we have completed in the Malaysian market. We constantly have to look at other markets and see what they can offer us, given the state of play in South Africa. We’ve been very successful in the DRC over the last four years, and we will head back there in the next couple of months to complete more projects. We feel that even countries like Zambia and Namibia hold promise for us, and we are really focusing on getting as much as we can from these territories.”