In an industry that is teeming with competition, Rako Tamperseal has managed to develop a strategy that has seen the company grow significantly in recent times. Investments into its African operations and its technology portfolio have been central elements of this strategy and MD Uwe Boegl tells Enterprise Africa that the company is targeting even more progress in the next five years….

Rako Tamperseal is one of South Africa’s most advanced manufacturer of eye catching labels and shrink sleeves that assist in the effective branding and protection of your products. Established in SA in its current form in 2011, Rako Tamperseal has seen impressive growth in the past two years, investing in new technology and building its customer base across the border in Africa.

The company supplies products and services including self-adhesive labels, shrink sleeves, tags and swing tickets and application machinery to customers across sub-Saharan Africa and it strives to be ‘your preferred partner for premium label and shrink sleeve solutions’.

Rako Tamperseal is part of the wider Rako-Group based in Witzhave, Germany and is proud to offer ‘German excellence proudly produced in South Africa’.

MD, Uwe Boegl recently spoke to Enterprise Africa and explained that in the past 12 months the company has seen a growth in turnover of 28% and growth in exports to Africa of 45%. Drivers behind this growth include investments in new technology and also a focus on developing business in Africa.

“The major reason for our growth is the broadening of our product portfolio,” he says. “We were only printing self-adhesive labels and tags but in 2014 we took over a company that converts shrink sleeves and we integrated that business into RAKO and being able to offer both shrink sleeves and self-adhesive labels opened new doors for us and we found new clients. That helped us grow in South Africa but since we noticed that the South African FMCG market was stagnating we took the decision to extend our market from South Africa and move further into Africa where we approached customers in the SADC region and we realised significant growth.

“We did also look outside the SADC region; we’re exporting into Tanzania, DRC and Ghana. There has been sustainable growth there so we are definitely going to intensify our activities further in these regions.

“We wanted to have a bigger footprint and looking at what’s happening in South Africa, we had to take some effective measures as the order volumes were coming down and the price was under increasing pressure.

“We have installed digital print technology to cater better for smaller and individualised print runs and we are now able to offer a competitive price for a premium quality. If we look at our export market, it’s a completely different scenario. There’s hardly any small orders. The export business consists of consolidated and bigger orders” Boegl explains.

ADAPTING FOR A SLOW ECONOMY

It’s no secret that the SA economy is struggling. Growth has slowed, unemployment is still high and major companies (especially in key sectors such as mining and construction) have had to cut staff because of the lack of investment in the country. This all filters through to the secondary and tertiary sectors leaving the future outlook uncertain. Three of the world’s largest credit rating agencies (Fitch, Standard & Poor’s and Moody’s) have hinted at downgrading SA’s economy, causing concern among investors and government. This has resulted in everyone being very careful about how and when they spend their money. But focussing on client satisfaction and being aware of industry traits has allowed Rako to adapt its strategy in SA and navigate these difficult times.

“We haven’t been affected by the slowing economy at all, we’ve actually seen growth because we have changed our technology and strategy accordingly and in time,” explains Boegl.

“What I’m seeing is people being more careful,” he says. “The majority of our clients used to order in bulk but now they are ordering smaller quantities in shorter cycles to reduce their working capital. At the same time successful retailers and brand owners have developed the African market for their business.

“We’ve stayed connected with our clients as they’ve moved into new regions and in doing so we’ve discovered new markets for ourselves where there is a lot of business opportunities we haven’t tapped before.

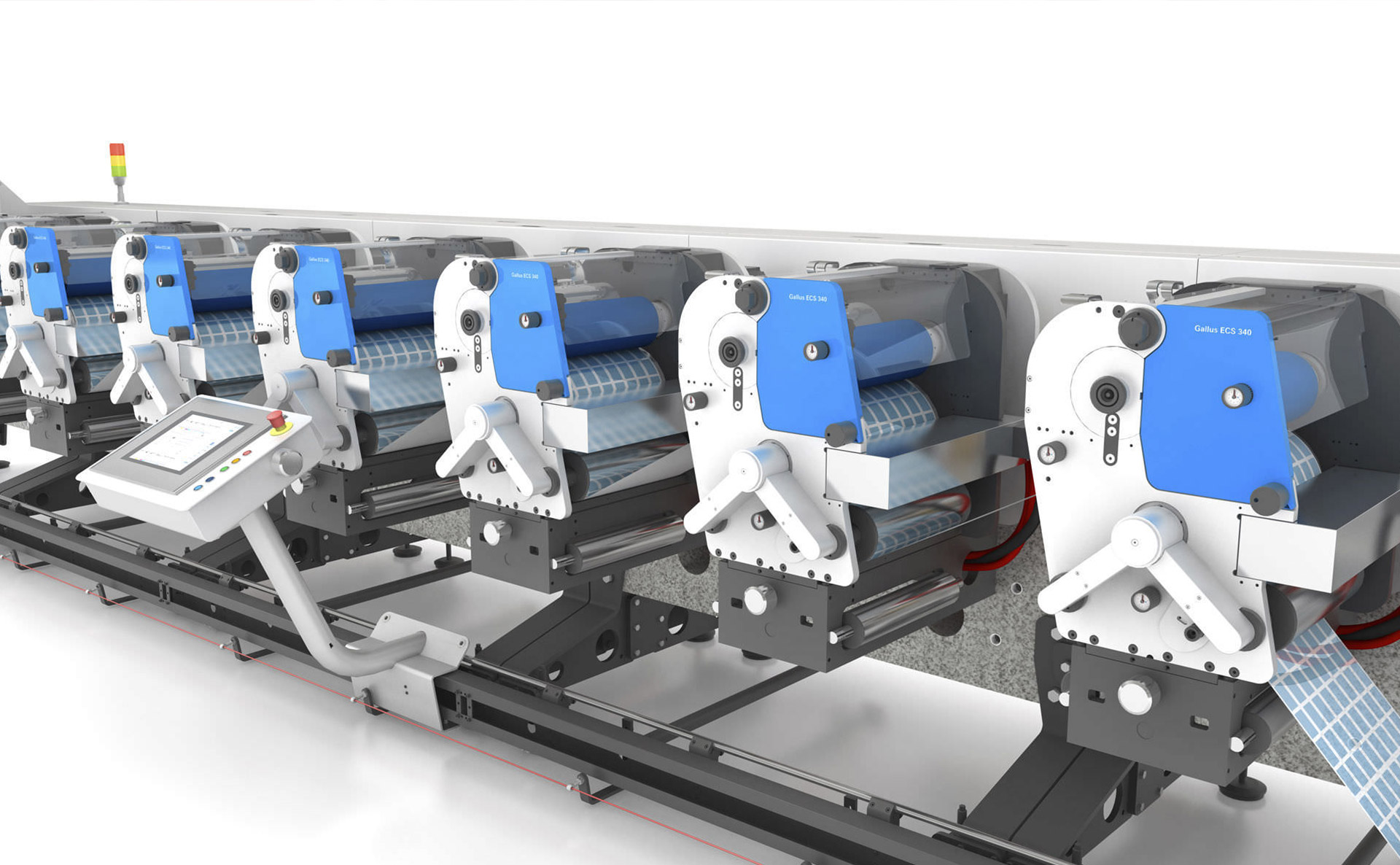

“For each market situation, you have to find the right marketing strategy to master challenges and threats. You can’t just change the market. If the market is slowing down then you have to find a strategy to survive and we changed technology to cater for smaller volumes while still making a decent margin. Based on our SWOT analysis we have not only changed our sales strategy, we also have changed our entire range of machinery. Not one of the machines we had in the factory five years ago is still here today. All of our printing presses have been exchanged to cater to the market and we’re just about to get another new digital and flexo print press which are specially catered for our high-quality print market. These latest technology presses are designed for easy and faster set-up and also reduce waste.

“At the same time, we have put a lot of effort into our R&D activities” says Boegl” so we introduced RAKO HO-Flexo, a technology substituting screen printing by high opacity flexo printing, RAKO bright shine, a technology to apply inline coldfoiling to shrinksleeves and last but not least RAKO brand fortress tamperseals, a shrink sleeve including a holographic strip to prevent counterfeiting of genuine brands. All these new developments have been accepted with excitement by our clients. Since we are a solution and service driven company we always strive to find solutions for our clients daily challenges.”

Investment in technology provides huge benefits in terms of offering higher refined labels, reducing lead times, increasing flexibility and operating as efficiently as possible but these investments come with a cost and this, of course, represents a risk. Fortunately, Rako utilises its relationship with its global group to leverage the best possible deal. Just recently, the company purchased a new, top-of-the-range HP Indigo WS6800 digital press to cater for short runs and this was after using the previous model for just two years. Further investments to increase capacity have been in a further 8 colour Gallus ECS340 UV-flexo press and a further sleeve converting line.

EVOLVING RAKO

As we move into 2016, Rako and Uwe Boegl have no intention of slowing the fantastic growth that the company has seen over the past 12 months. In fact, there are plans in place to drive the company towards an extremely bright future, despite the miserable economic outlook in South Africa.

“We have a growth plan for the next five years to double our turnover and we’re very confident that we can achieve our goals,” says Boegl. “We’re still quite small and that means we’re much faster in reacting to changes in the market and I believe there are a lot of changes happening in Africa. It’s very different to the European market where you can have fairly reasonable forecasts; in Africa things are very unpredictable. Being part of a big international group, we have that financial background to invest if need be – whenever we see the potential for growth or a change in technology then we can react immediately.

“Our management here is flexible enough to work quickly when reacting to changes in the environment,” he adds.

Even though Rako Tamperseal is part of the global Rako-Group, a 1500 employee organisation with roots going back to 1969, the South African operation enjoys decision making freedom and is not stifled by its parent.

“The group consists of nearly 20 facilities worldwide and each facility runs its own business. We are completely responsible for our own budget as well as our strategy,” explains Boegl. “There are core areas of our business which are defined by the group. We are very clear on the type of products that we want to produce. It’s very clear that our portfolio is in flexible packaging, labels and shrink sleeves. We will not be going into rigid packaging, we will focus on high-value added products and high-quality printing. These strategies are set by the group along with the technology we use but sales, marketing and budgeting is completely independent.”

Utilising this independence, but following the lead of Rako globally, Rako Tamperseal is targeting the environmental side of its operation. The nature of the business does not lend itself to being a very ‘green’ operation but Boegl believes there are solutions to be had.

GREEN IDEALS

“Most packaging is not environmentally friendly by its nature but they are protecting and decorating goods for transport and retail,” explains the MD. “What we’re doing to reduce that, through a strong strategy in place across all our factories, is to look internally at how we can reduce waste as that’s a big factor in our industry. We have a very strong focus on waste reduction as it has an environmental and commercial benefit. We want to recycle as much as possible. We have found facilities to recycle our ink and chemical waste, we are in talks with PET manufacturers, with recycling capabilities to recycle our polyester waste. Most of our other waste materials are multi-layer laminates with ink which are challenging for recyclers.

“Our waste would be a perfect fuel for an incineration plant that could generate electricity. There isn’t a plant like this in the Western Cape but we hope invetments in this direction will happen here soon,” he says.

The development of a recycling/waste management initiative that could benefit the entire packaging/labelling/branding industry and wider manufacturing industry is something that will require the work of all players involved and not just Rako.

“I believe there will be a change in the near future where people will look at how they can reduce their wastage by as much as possible but it has to work in an industrial environment, on a large-scale,” says Boegl.

“That is a task for the entire industry; to stand together and establish a credible recycling infrastructure,” he adds.

Combine this effort with the ambitious African growth plans and the constant investment into technology and you begin to realise that Rako Tamperseal is a company that will ride the economic wave and come out the other side in an industry leading position.